The use of robotics in manufacturing is becoming increasingly common in many industries, including metal and machine industries. Robotic systems can offer significant advantages over manual labor, such as increased productivity, faster turnaround times, and fewer errors. As technology advances rapidly, robotics allows these industries to stay competitive while maintaining their focus on quality and cost-effectiveness. This article will discuss how robotics in the metal and machine industries can empower manufacturing.

Automating Production Processes

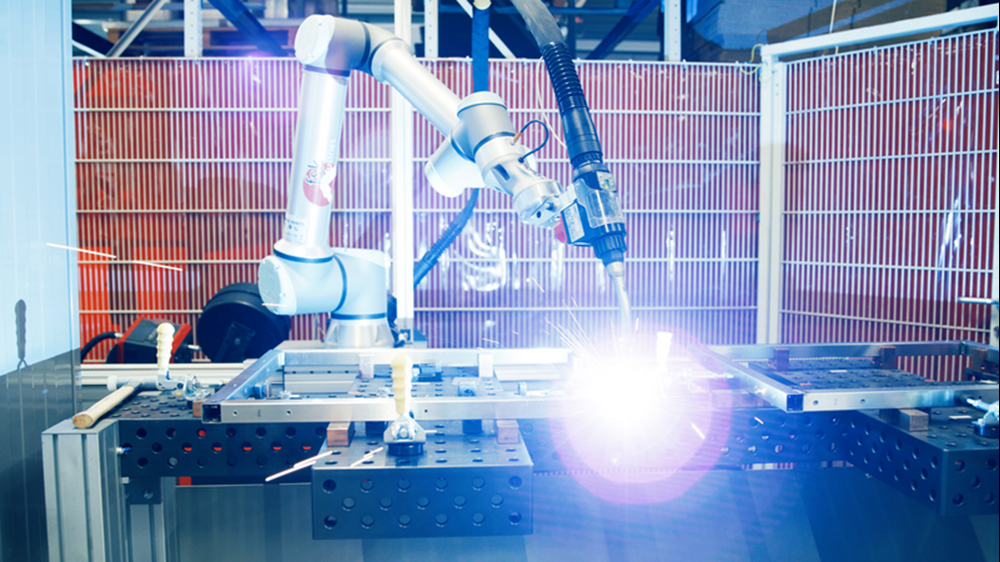

One way robotics can empower the metal and machine industries is by automating production processes. Automation allows faster and more accurate production, translating into a higher quality product in less time. It also eliminates manual labor, making it much easier to keep up with demand.

By using robotic systems to automate more of the production process, manufacturers can increase efficiency while decreasing costs. Therefore, they can produce products at a lower cost and shorter timeframes than before, giving them a competitive edge. It also enables increased accuracy, allowing them to produce products with fewer defects.

Reducing Manual Errors

Another way robotics can empower the metal and machine industries is by reducing manual errors during manufacturing processes. In the metal and machine industries, using robotics eliminates the need for manual labor and dramatically reduces errors.

With robotic systems, the production process can be highly accurate, ensuring that all parts and components are produced correctly. It reduces time spent on manual inspections and increases the quality of the finished product, resulting in fewer defects overall. Robotic systems can also be programmed to detect potential issues during production, improving accuracy.

Increasing Speed

Robotics can also empower metal and machine industries by increasing manufacturing speed. Using robotics, manufacturers can produce goods faster than before while maintaining high-quality standards. Automation allows for rapid production with minimal human intervention, enabling a shorter turnaround time between orders. Robots can work 24/7 without needing breaks or rest, resulting in greater efficiency and productivity than manual labor. It also reduces the overall cost of production, as robots are cheaper to operate than manual labor.

Enhancing Safety

Robotics can also enhance safety in metal and machine industries. By using robots, workers are exposed to fewer hazardous materials and conditions. Robots can work in areas that may be too dangerous for manual labor, such as high-temperature environments or hazardous substances.

They can also complete tasks with precision and accuracy, reducing the chances of accidents or injuries. Robots are generally more reliable than humans when completing difficult or complex processes. They can also detect potential hazards and alert workers to take necessary safety precautions.

Streamlining Supply Chains

Machining robotics can help streamline supply chains for manufacturers by optimizing inventory management. With robotics, manufacturers can accurately track their production processes from start to finish, allowing them to better understand where their products are in the supply chain at any given time. It helps them plan and react quickly to changes in demand, ensuring that their products are always available when needed. By automating inventory management with robotics, manufacturers can reduce unnecessary costs and save time, ultimately improving their bottom line.

Reducing Production Costs

Robotics can help metal and machine industries reduce production costs. Robotic systems require less energy than manual labor, allowing manufacturers to cut operating expenses. Automation also eliminates the need for expensive raw materials or components since robots can produce parts faster and more accurately than humans.

Robots don’t require wages or benefits like human workers, reducing overhead costs. Robots can be programmed with specific tasks, allowing manufacturers to produce products with fewer defects and less waste. It ultimately saves them time and money.

Improving Customer Service

Robotics can help improve customer service in the metal and machine industries. Robots can be programmed to provide customized customer solutions based on their requirements. They can also process orders quickly and accurately, delivering goods faster than manual labor. Automation ensures that products are delivered with high-quality control and accuracy, resulting in fewer customer complaints. It helps manufacturers maintain a good customer reputation, ultimately driving sales and profitability.

:max_bytes(150000):strip_icc()/GettyImages-1394348691-fb6ac3222111498bb8c399ece71b9dfa.jpg)